- February 26, 2026

-

-

Loading

Loading

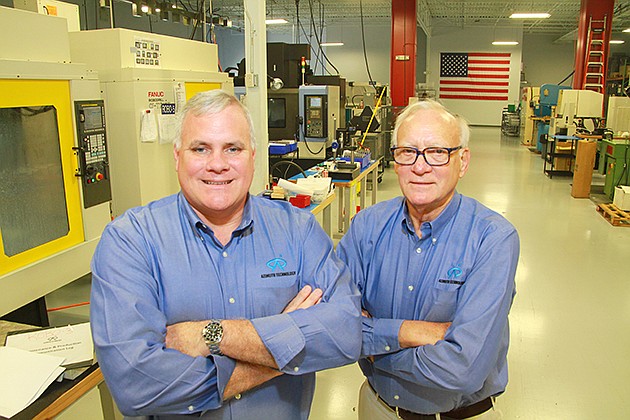

The founders behind Azimuth Technology LLC made a multimillion-dollar decision five years ago: When they launched the business, a Naples-based contract manufacturer, they did it with several licenses and certifications in hand.