- July 26, 2024

-

-

Loading

Loading

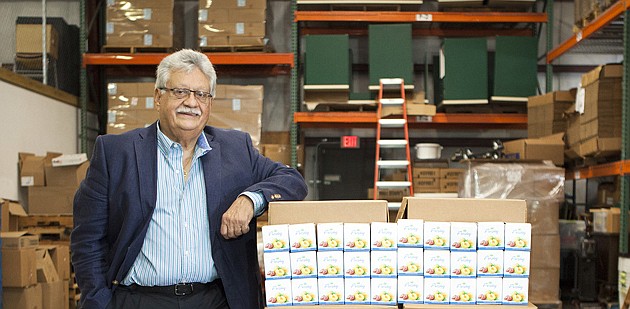

When Carlos Fuentes was asked to take a technology global, he knew he had significant to-dos before he could bring it to market, including securing a patent, completing validation studies, and hiring a marketing arm.

Two years after he was promoted to president of C-5 Biotechnologies, he's finally seeing the distribution deals that took eight years and around $4 million in investment.

The company's main product, Freshy, is a plastic egg filled with spring water infused with a proprietary mix of minerals. When placed in a refrigerator, the company says the egg omits a 3-foot radius of naturally occuring energy that keeps food fresher. The energy helps the food retain moisture and reduces oxidation and bacteria, extending the food's shelf life.

With the egg, strawberries that may last three or four days can last 10 to 12 days, Fuentes says. It will also enhance the sweetness of the fruit. The egg, which sells for $19.95, or $29.95 for a two-pack, works for up to a year.

Freshy is currently sold on Amazon and and the company's website, freshyworks.com. In the last couple months, the company sold between 1,500 to 2,500 Freshy units, “which is just the beginning,” Fuentes says. He's waiting to finalize a deal with a television shopping network and a distributor in China. If the China deal goes through, the company will need to supply 250,000 units this year. The TV network deal will require 25,000 units.

Fuentes says the company is ready to quickly ramp up manufacturing.The company has already looked at renting an additional 10,000-square-foot space if the deals go through. To fulfill the future increases in demand, Fuentes estimates the company will need another $250,000 in funding. “If I get the purchase orders, I'll get the funding,” Fuentes says.

The company's initial funding came from its founders and business connections, Fuentes says. He says some of those investors have continued funding, either to gain more equity in the company or as interest-only loans, but current investors have already committed to supply the capital needed to ramp up production.

The five-person company expects to hire 10 to 20 employees once the contracts are finalized. He says he has a comfortable timeline before the product needs to be delivered, ranging from three to six months, depending on the deal.

Fuentes believes the breakeven point will occur in about six months. “Once we get these orders, we establish credibility in the marketplace and we'll move forward quicker,” he says. The TV deal won't be as profitable because, like a Publix or Walmart, “they drive a hard bargain and they call the shots,” Fuentes says. But in terms of product validation, the deal is invaluable and could help him get the product in big-box stores like Costco.

To score the deal with the TV shopping network, Fuentes had to back up his product with independent validation studies. Through testing with Microbica Laboratory Partners in Clearwater, the Freshy line was able to pass this filter in the first half of 2013, Fuentes says.

Once the global distributors receive the product, C-5 Biotechnolgies is relatively hands-off. “We have nothing to do with the shipping or nationalizing the product in foreign countries or the government approvals,” Fuentes says, adding that they let the distributors take control. “All products are delivered FOB Florida.”

In exchange, international distributors have freedom to change the name of the product, develop the pricing strategy, and contract out to local distributors. For the China deal, Fuentes agreed to ship the product in bulk for the distributor to handle individual packaging, since it will need to be completed in a different language.

In preparation for the product's release, the company established a partnership with a marketing firm as a joint venture, Jamm Brands, based in Jacksonville, which helped launch a website and public relations plan.

“We look for expertise,” Fuentes says. “That's why we don't have an in-house marketing arm. We're manufacturers, not marketers.”

Keeping manufacturing close to home is key to their success, Fuentes says. “The bottom line cannot be the only concern and cannot be the determining factor. You see quality being impacted by outsourcing, even copying your product- factories opening up a third unauthorized shift.” Although he doesn't believe the product can be reverse-engineered, “keeping close to your heart is best,” Fuentes says.