- July 26, 2024

-

-

Loading

Loading

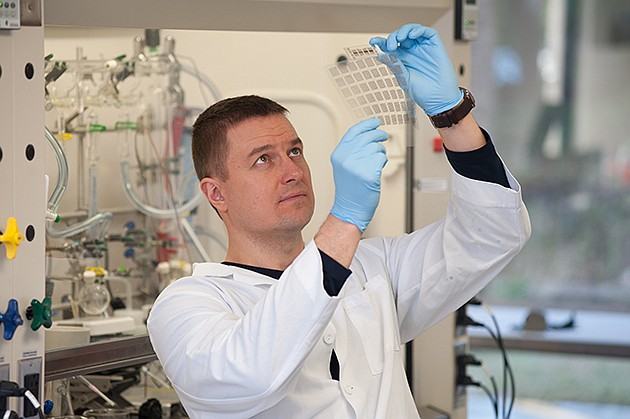

Sarasota chemist and entrepreneur Alexey Gusev grew up in Moscow, so the cold and dreary winters in northwest Ohio were a cinch when he earned a Ph.D. at Bowling Green.

It was the drastic differences between the socialism he knew as a child and the capitalism he encountered in the States that really left an imprint on Gusev. And when faced with a choice of chasing a tenure-track job in academia or starting a company, Gusev chose the latter. The raw get-it-done-or-else value system of running a business, he says, was more enticing than the cushy comforts of a teaching gig. “From day one,” says Gusev, “it's been a race to have a revenue product.”

That race, with a company Gusev co-founded in 2010, US Nano, could be nearing a key milestone. In June, the Sarasota-based company plans to hold its final test runs for its patented core product, nano-biosensors. After that, Gusev believes US Nano will move into sales mode.

The biosensors, says Gusev, work just like a larger silicon conventional semiconductor, but are actually composed of super-tiny inks made with nano-materials and nano-wires. The inks, printed onto nearly any kind of surface, form a rugged layer that can bend without breaking and manipulate light and heat — a significant commercial development, says Gusev. And by shrinking the size of a traditional semiconductor, US Nano's products can go places other sensors can't.

US Nano's business model is to license its nano-biosensor technology to a host of companies that manufacture products where having small sensors is essential. Industries include energy, consumer devices, health care and defense.

Possible clients US Nano has already talked to about sales range from an aquaculture firm in Sarasota to a company building flat screen TVs in Germany. Another potential partner: Lakewood Ranch-based RPS Diagnostics, which develops quick-use tests for infectious diseases and inflammatory conditions.

“If we are successful this has big implications,” Gusev says. “There are a lot of big pain points for businesses we can eliminate with our products. There are a lot different applications for what we have developed.”

For example, the US Nano biosensor technology can be used in RPS's pink eye detection test, to improve the device's accuracy and efficiency. Gusev also says the company's technology can be used in biomarkers that help farmers see if a cow is pregnant or sick.

A major pain point for US Nano has been speed to market. It's taken six years, nearly a dozen employees and close to $4 million just to get to the point where it might have something commercial viable.

The company was launched at a University of Notre Dame tech incubator, which provided an initial round of funding. Current funds to support research and development include private investors and a $1 million National Science Foundation grant. And Sarasota County gave the firm $3,000 in incentives for eight newly created full-time jobs when it moved from South Bend, Ind., in late 2014.

“It's a really exciting time,” says US Nano Vice President Louse Sinks, who has a Ph.D. in chemistry. “Everything is finally coming together.”

The specifics of the delays start with nanotechnology itself. Gusev acknowledges the industry has traditionally been long on promise, short on results. One issue, he says, is there is a shortage of successful nanotechnology companies, which leads to issues with sourcing materials. Says Gusev: “The field has a big problem in its supply chain.”

One delay internally has been space. The firm moved into its current 5,000-square-foot home, in an industrial park just north of downtown Sarasota, in early 2015. It cost more than $500,000 to build a state-of-the-art nanotechnology lab, including $200,000 in specialized air-handling equipment to provide a clean environment.

Lab equipment includes a scanning transmission electron microscope, with a specialized spatial resolution to see the nano-materials, which cost around $200,000. “It was a bit of a process,” says Sinks, “but now we have the space to do what we want to do.”

Gusev says those wants are big, and he believes US Nano has the right entrepreneurial mindset to shift to market needs as necessary. “Real innovations almost always come from a small company,” says Gusev. “Big companies play it safe and are too conservative.”

Follow Mark Gordon on Twitter @markigordon