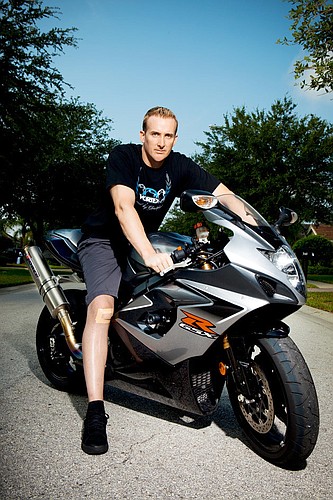

Matt Griffin, 39 Vortex Racing

Those sleek, speedy racing motorcycles that bank around tracks and fly through the air over muddy hills, need handlebars, sprockets, clutches, brake levers and other parts.

That's where entrepreneur Matt Griffin, 39, comes in.

Griffin used to race motorcycles before he got injured. Griffin broke seven bones while his business partner Daniel Geberth broke at least 20.

The two childhood friends from New Jersey eventually moved to Tampa Bay and opened Vortex Racing in 1995, to make and sell parts to motorcycle companies.

Today, using 3,000 dealers and 30 employees, they sell more than 28,000 Vortex products for adrenalin junkies who ride what are called “crotch rockets,” also known as racing or dirt bikes.

To help market Vortex, the company also sponsors pro and amateur racing teams, including the U.S. Yamaha Racing Team. Vortex has seen its name featured in two PlayStation games and in the 2004 biker movie “Torque,” starring rapper Ice Cube.

Griffin and Geberth dreamed of starting a business in the industry. After high school, Geberth left for Florida, where he got work in a machine shop. Griffin, who knew how to program milling machines, joined him after college, three years later in Palm Harbor.

They rented part of the machine shop where Geberth worked to develop some prototypes. They called their company Gearz, because that was they wanted to make. But they changed that to Vortex as their vision grew.

Their start with Vortex was slow. They drove their own truck through the night to deliver parts to other states, such as Michigan. At first, they used their machine shop to make arrowheads for archery companies because they weren't getting enough orders for sprockets and handlebars.

They cold called and tried to run down cycle company executives at conferences.

“There were a thousand no's for every yes, at the beginning,” Griffin says. And there were tough lessons.

In 1996, after struggling to get one sale, Vortex got an $800,000 order and bought two new machines to handle it. But the customer later cancelled the order.

But they believed in the popularity of the sport. Both say their youthfulness has turned out to be an asset when dealing with motorcycle parts distributors because they expected them to be around the industry for a while and they trusted that they knew the products and the market.

But those relationships took a while to establish. After renting space, Vortex built a building in the West Pasco Industial Park. It then built a $1.1 million office and industrial building, more than twice the size of its original building, about 2½ years later in Odessa.

The company used the profits from selling its former building in the West Pasco Industrial Park to pay off debt from its recent expansion.

Today, it operates a 22,500-square-foot facility, with computer-aided design and mails out its parts to companies around the world. New manufacturing techniques have cut down production time. A new rapid prototype machine turns out plastic replicas of newly designed products and a 3-D printer helps company engineers envision new designs.

To differentiate itself, Vortex likes to use different supplies, such as aerospace aluminum for its sprockets.

Vortex also sells a line of branded clothing, including shirts, shorts and hats, which is growing in sales. It also invents his own parts.

There are several competitors that match Vortex's product line. But most specialize in one or two kinds of parts.

“No one does our diversity,” Griffin says. “We're a one-stop shop.”

The biggest challenge for Vortex is keeping up with industry trends and motorcycle redesigns.

“We're not always making 10,000 of one part,” Griffin says. “We're looking for the latest, greatest thing. Then we need to go on to the next thing.”

Vortex has gone to Germany to one of the world's biggest automotive trade shows because the strength of the Euro has made American-made products look like bargains overseas.